| OK, so sometimes things don't turn out the way you planned. Sometimes

the top wing goes on a bit crooked, or the struts don't quite

reach. Occasionally a large fingerprint ruins the finish or the

colour scheme later turns out to proved wrong.

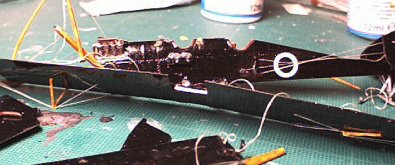

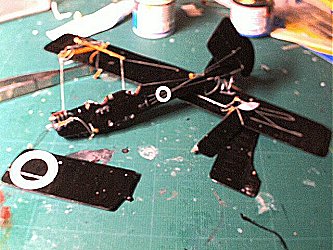

This is as nothing compared to the Great Modelling Disaster. This page recounts the story of a BE2e and is not for the faint-hearted. Be warned Brothers and Sisters... The model in question was a resin kit bought some years back. Its origin is unknown. It carried no manufacturer's mark anywhere and contained no decals. Instructions consisted of an exploded diagram only. But the casting was good, very fine detail and no bubbles anywhere. I started the model in October 2000. It went together so well and boy did I have a colour scheme to impress you all. - A Blue Rider decal sheet bought at the 2000 IPMS UK bash was the source. My BE2e was to be a Home Defence Squadron machine, alleged to be black overall with white outer roundels. It took me six weeks to assemble the kit and apply a glossy black finish. I spent a week on achieving a lovely pine finish on the struts. I finished the model at about midnight on Saturday, 25 November

2000. It looked WONDERFUL, but...

Sunday arrived for me at about 10 a.m. After breakfast, I went into my workroom to admire the model and think about taking it outside to photograph it in the bright morning sunshine. Life was good. But then I noticed... I must have wrapped one of the elastic - thread

rigging wires the wrong way around the bottom of an outboard strut. Just then, for reasons I cannot understand even now, my hand twitched. The tweezers twisted the strut at the base. There was a loud *crunch* as the elastic thread I'd used for rigging snapped back to its original size - and the entire model collapsed. Sickening. I remember walking downstairs clutching a handful of resin bits and a

tangle of threads. By the time my wife saw me I was shaking like the

proverbial leaf. I took the photos below after I'd decided that if you can't laugh, you'd cry. SIX WEEK'S WORK !

|

||

|